Although it is not the millwright or mechanics responsibility to specify mechanical seal applications, it is a good idea to have a basic understanding of their purpose. This blog will give the basics of double and tandem mechanical seals.

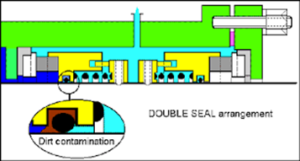

The double mechanical seal uses two mechanical seals (an inboard and outboard seal). They can be installed back to back, front to back or front to front depending on the application. Double seals are used when leakage of pumped fluid to the atmosphere is not allowed.

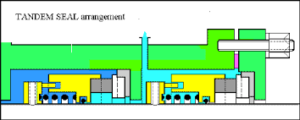

Tandem seals are two single seals mounted in the same direction. Tandem seals are used for toxic or flammable liquids that require a buffer or safety zone. If the inboard seal fails, a high pressure alarm will activate to provide a warning that the inboard seal has failed. A tandem seal with an inboard seal failure no longer has an effective safety zone.

For more in depth information on mechanical seals, I highly recommend contacting your mechanical seal supplier. They are usually very willing to help.