When using the Smart Machine Checker (SMC) or any of Acoem’s Condition Monitoring Tools, there are typically only two variables you need to know for an accurate diagnosis of your machine. You need the horsepower of the motor and the correct rotating speed. This information will usually be stamped on the motor data plate. But if the motor is being driven from a variable frequency drive (VFD), the speed can vary and the data plate speed will be incorrect. If this is the case, you still need to calculate the rotating speed. You can use the SMC’s strobe light to fine tune the exact speed later.

The VFD will typically display the motor speed either in frequency (hertz) or percentage. The panel below displays the frequency and is set to 44.6hz.

To find rotational speed (RPM or CPM), I used the display frequency of 44.6 and divided it by the normal incoming line frequency of 60hz. The result was .743. So 44.6/60=.743

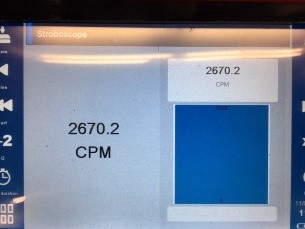

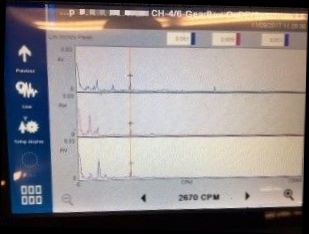

Then I used the data plate rated RPM of 3600, and multiplied it by the factor of .743. The result was 2674.8 RPM or CPM. After entering this value into the tool, the actual frequency spectrum generated by the SMC instrument verified this to be extremely close.

This method will give you a good starting place for entering the speed of the rotating machine into the SMC. The instrument has a built-in stroboscope to verify and pinpoint the exact speed for added accuracy.