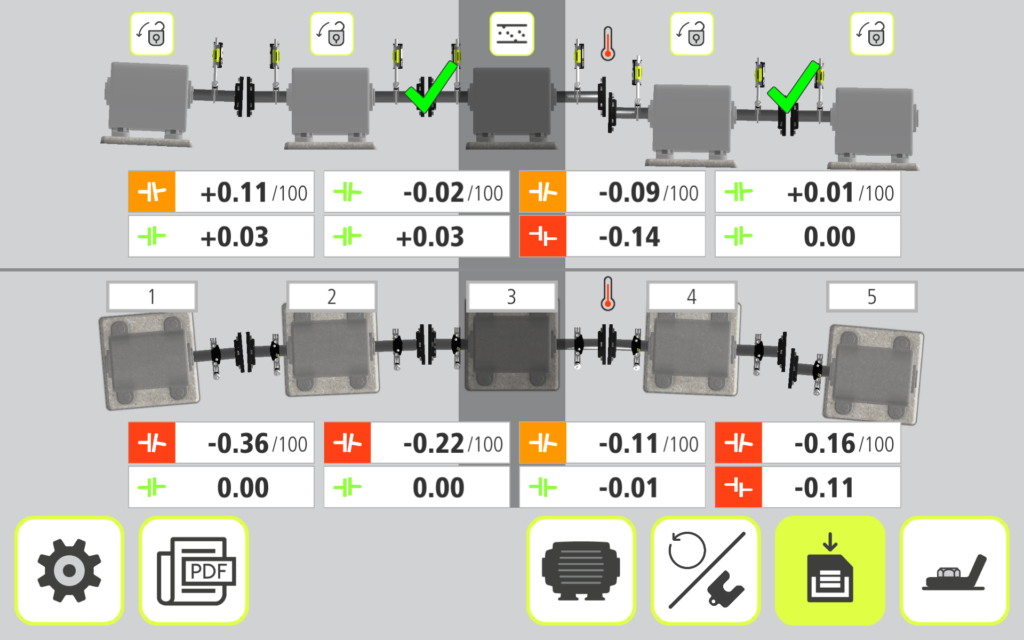

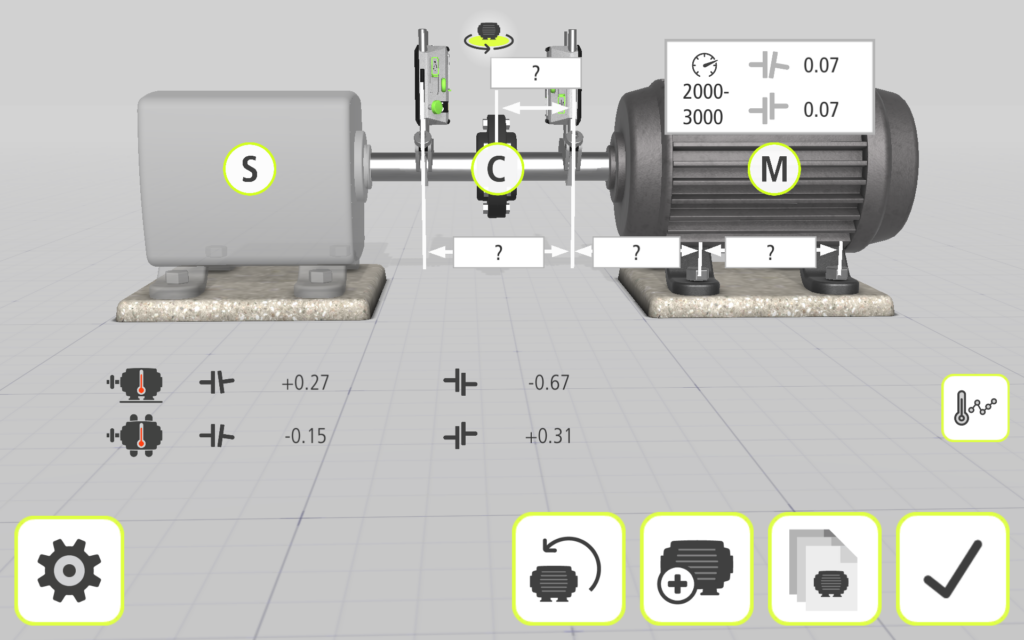

GuideU™ Interface

GuideU™ is the next generation of 3D shaft alignment graphical user interface – our patented, customizable, icon-driven and color-coded display system that makes measuring, aligning, and reporting simple. Featuring realistic machine graphics and animated help screens, the risk of human error is minimized to take the guesswork out of shaft alignment.

Cloud Connectivity

Supplied with cloud connectivity, the AT-300 allows users to effortlessly upload alignment reports to Acoem’s proprietary web portal, ensuring seamless data management and easy access to alignment records for analysis and comparison. With just a tap of a button, technicians can send their alignment reports directly to the portal, streamlining their process of documentation.