Performing Precision Shaft Alignments on Cooling Towers present a unique set of challenges. A recent job is typical of what I find. We were originally called out because on three cooling towers the motors were experiencing high vibration.

Some of the challenges include:

1 – Access through shrouds

2 – Ladders often required to gain access to gearbox shafts

3 – Flimsy structures

4 – High vibration from nearby equipment

5 – Still need to perform prealignment checks such as rough alignment, gross soft foot checks, bolt tightening sequence and final soft foot check. These steps are critical on all alignments but especially true here since you want to minimize climbing ladders. Rough alignment can be especially critical.

Essential PreAlignment checks video

Cooling Tower Access

20 foot extension ladder required for access

Motor sensor was able to be mounted inside the shroud so cutting of the shroud was not required.

Minimizing climbing is imperative – prealignment is critical

Issues and results

1 – Cooling towers 1 and 2 were on a common trough and Cooling Tower 3 was by itself. Measurements on Cooling Tower 3 were able to be taken with 1 and 2 running. When it came time to align 1 and 2 Cooling Tower 3 was turned on full and Cooling Tower 1 or 2 were run at half speed. This allowed good measurements to be taken.

2 – The motors were all high with 1” master shims under each foot. The laser beams were used to rough align the machine and the master shims were replaced with much smaller master shims which allowed the alignment to be completed.

Long Span Rough In – http://acoem.us/shaft-alignment/roughing-in-for-alignment-of-long-spans/

3 – The spacer shaft function was used which displays the alignment results as angle/angle (the angle at each flex point) instead of total angle of the motor to gearbox and offset ½ way down the spacer shaft. The sum of the angles at each flex point will equal the total angle but that will be the subject of another blog post.

Results (all towers were similar so Cooling Tower 3 is used to illustrate)

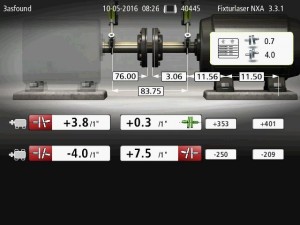

As Found

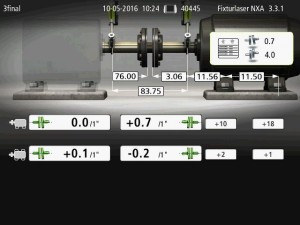

As Left

End results were much lower vibration levels on each tower.

Other blog posts on Cooling Towers can be found at: