While V-belt sheave alignment tolerances are not as precise as tolerances for precision shaft alignment, they are important. Proper sheave alignment (along with correct belt tension and proper ventilation) will:

- Increase Belt and Sheave Life

- Minimize Vibration

- Reduce Heat (Friction) from V-belt/Sheave Contact

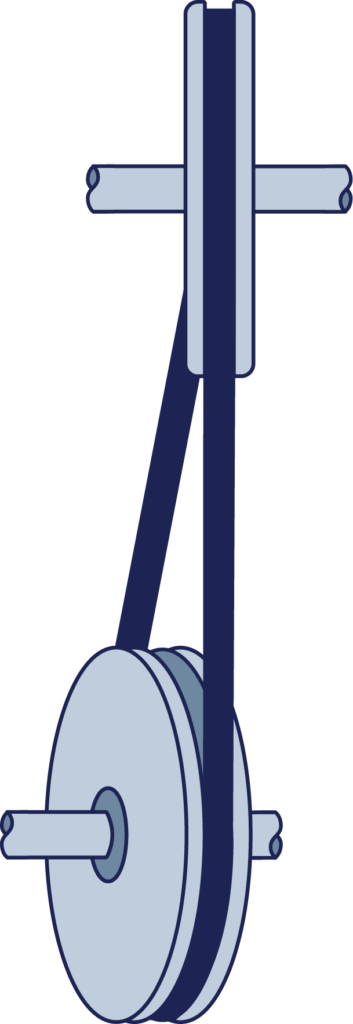

Types of V-Belt Misalignment

Just like for shaft alignment, there are two main types of sheave misalignment, Offset and Angular.

Sheave Angular Misalignment

Problem: The shafts of the driver and driven machine are misaligned.

Solution: Correct by shimming either both back feet, or both front feet, of the driving machine.

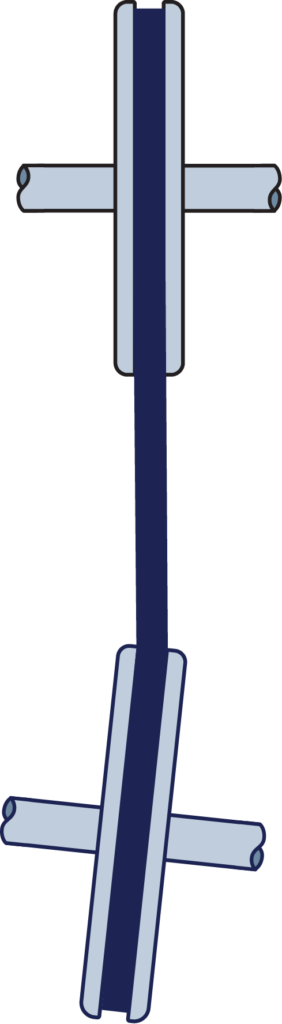

Shaft Angular

Misalignment

Problem: The shafts of the driver and driven machine are horizontally misaligned.

Solution: Correct by moving either the back or front of the driver. The shafts are now aligned, but the sheaves may not be.

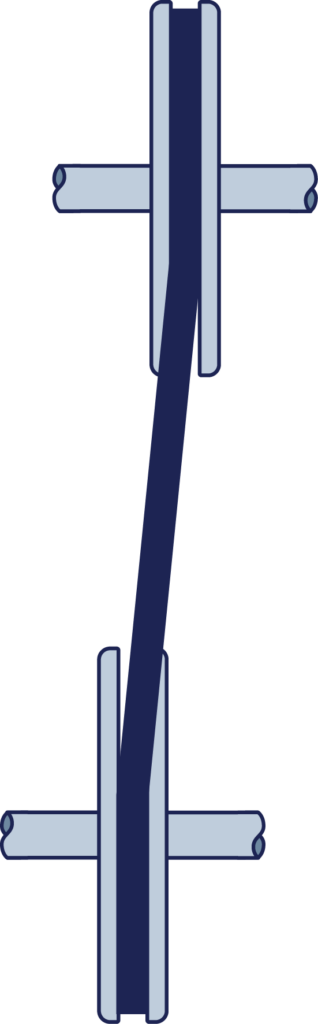

Sheave Offset or

Parallel Misalignment

Problem: The shafts are aligned, but the sheaves are not.

Solution: Correct by moving one or both sheaves along the shaft.

Beware of "drawback" when using taper lock bushings.

V-Belt Tolerances

Gates©, a reputable manufacturer of v-belts, recommends the following tolerances for sheave alignment:

- Angular Misalignment: 1/2° degree (1/3° for SAE applications and 1/4° for synchronous belts)

- Offset (Parallel) Misalignment: 0.1 in/foot between shaft centerlines

Here at Acoem, we typically recommend angularity of 1/2° angle and 1/16” (0.062”) per foot offset.

Alignment with the Belt Hog

A view of the small and large graduation marks labeled on top of the Belt Hog pulley alignment tool.

On the Acoem Belt Hog (Know as PAT outside of the U.S.), the increments are as follows:

- 1 Small Graduation = 1mm

- 1 Large Graduation = 5mm

So, any easy way to confirm alignment precision would be:

- An offset of one small mark per foot of the distance between shaft centerlines, which would equal 1mm (0.039”).

- An angularity of 1/2 mark for every foot between shaft centerlines, which would equal 1/2° degree.

As an example, if my shafts were four feet apart, a good alignment would be:

- 4 marks or less difference on the offset.

- 2 marks or less difference on the angle.

Conclusion

Again, the tolerances in V-belt sheave alignment are not as precise as you will find with shaft alignment, but they still matter. It is integral to keep your belt-driven equipment aligned within tolerance to maximize the lifespan of your belts, minimize vibration, and keep your equipment running reliably. Please leave us a comment if you have any questions about belt alignment or tolerances. As the Reliability Partner, it is our mission to help you transform your approach to maintenance and reliability.