Documenting and saving alignment data is critical to being able to achieve repeatable shaft alignments. It also helps you maintain an effective predictive maintenance plan that will ensure your plant runs smoothly.

When a machine is experiencing a problem, it will save a lot of time if you can look back on recorded data from previous alignments and have insight to diagnose and fix the current problem.

Documenting alignment data is also important when multiple people work on the same machine. For example, if the machine develops a problem after a technician performed an alignment on it, or were to experience failure as a result of something other than misalignment, having a saved record of the alignment quality would rule out misalignment as a cause and ensure the technician is not blamed for the problem.

Another reason why documenting alignment data is important is because some regulated industries require compliance with certain specifications, and you will need to have documented proof that those specifications have been met.

So, what information should you be recording and saving?

Here are several things you will want to document:

- Machine information–it’s number, whether it’s a critical machine, etc.

- What maintenance, if any (lubrication, bearing replacement, alignment, etc.) was performed at the last check

- The date you last performed maintenance on the machine

- Whether the machine was running at the time

- Any issues that need to be addressed on the machine

- The person who checked the machine (so the right person can be contacted if a question arises later)

Next, where should you store the information you document?

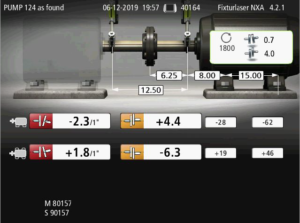

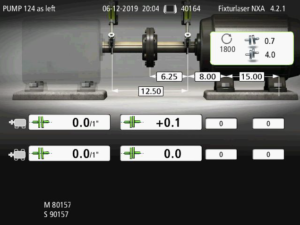

If you are using one of VibrAlign’s alignment tools (NXA, EVO, ECO), recording and saving alignment data is simple. Once you perform an alignment, you have the option to save your data and add your desired input.

Regardless of how you store the information you record however, the important thing is to have an organized system. Make sure to follow a consistent pattern when labeling machines and processes so that you are easily able to search for them later.

Although documenting alignment data can seem time-consuming and work-intensive on the front end, it is essential if you want to achieve and maintain a successful predictive maintenance plan. Plus, you will thank yourself when you wish you could remember what you did to get machine X into tolerance last time, and you have saved alignment data to look back on.

Below are some examples of how you can easily save alignment data using our Fixturlaser NXA:

Photo courtesy: iStockphoto.com/SARINYAPINNGAM