The object of precision shaft alignment is to position machines so that the rotational centers meet a specified tolerance at operating conditions. Machines can and will move due to temperature changes or process forces so this means that some machines need to be “misaligned” in their off line or cold condition so that they will be precisely aligned when they are operating. Compensation for growth can be accomplished with many laser systems but people sometimes get confused over how to compensate for it. Of course, this only works if the targets are correct but that is a discussion for another time.

Growth versus Targets

Thermal growth is the actual relative change in positions of the moveable and stationary elements. Target values are the compensation for that growth. Target values can be entered into all Fixturlaser GO and XA alignment systems. Assuming the targets are correct, the user can align to his angle and offset tolerances and the machine will end up “misaligned” cold but will grow into alignment when running.

Example

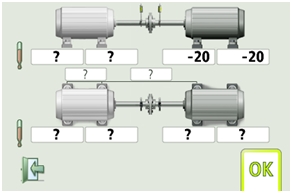

If the motor were to grow 20 mils (20 thousandths) and the pump does not grow then the target values would be -20 mils at both motor feet (or -20 mils at the coupling with a 0 mils/inch angle).

Inputting Offset Information Into the Fixturlaser GO Pro

1 – Select targets (thermometer)

2 – Select either feet values or angles/offsets

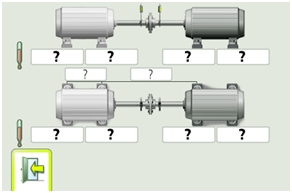

2 – Select either feet values or angles/offsets 3 – Feet values screen

3 – Feet values screen 4 – Targets of -20 mils at the feet of the motor

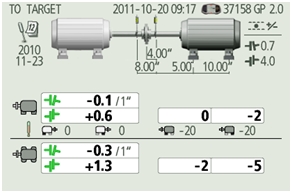

4 – Targets of -20 mils at the feet of the motor 5 – Aligning to targets (see thermometer in upper right-hand corner)

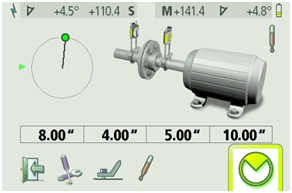

5 – Aligning to targets (see thermometer in upper right-hand corner) 6 – Aligned with -20 mil compensation

6 – Aligned with -20 mil compensation

Are you inputting target values for your alignments? How do you decide which ones are offset and which ones aren’t?

1 Comments

[…] thermal growth must be factored as part of the alignment process. […]