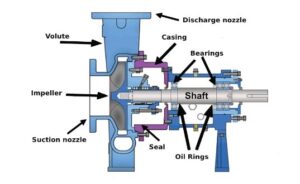

Recently I conducted training at a location that had quite a large population of centrifugal pumps, the majority of which were overhung pumps. As you can see from the diagram below, the overhung pump casing bolts to the volute by a ring of bolts in a circular flange.

Typical Overhung Centrifugal Pump

Issues with Bolt Bound and Base Bound Conditions

What was occurring after a rotating element replacement was either a bolt bound or base bound condition at the electric motor that was not present prior to the replacement.

The issue? If that ring of bolts is not tightened down evenly, in a cross-torquing pattern, it can change the pitch (angularity) of the centerline of the shaft. In other words:

- Tighten the top more than the bottom and it raises the centerline of the shaft

- Tighten the bottom more than the top and it lowers the center line

- Tighten one side more than the other and it changes the centerline

One way to witness this phenomenon is to tighten that ring of bolts while using your alignment tool is mounted and in live mode.

Of course, this is NOT how you perform the precision shaft alignment, as the casing flange bolts must be tightened down evenly to maintain proper gasket sealing and impeller to volute clearances.

Remember, it’s the little things that can cause perplexing challenges when performing precision shaft alignment!