From one organization to the next, the design of a reliability program will always reflect unique business needs and functions. Yet every program shares the same core objectives that form the foundation of Reliability-Centered Maintenance (RCM):

- Preserve equipment and systems

- Identify potential failure modes

- Assess the impacts of failures

- Apply the most effective maintenance strategies for each asset

Each of these objectives branches into countless sub-strategies, procedures, and tasks. They define what people do in a reliability program—but what often gets overlooked is the human component: the shared understanding of why these efforts matter.

Without a clearly defined “why,” individuals risk slipping into silos, following procedures without context, and ultimately stalling organizational growth. This is where culture comes into play—the collective mindset that gives meaning to the “why” and ensures that reliability isn’t just a set of tasks, but a way of working.

Defining Reliability Culture

Culture, in any organization, is the collection of shared values, beliefs, and behaviors that shape how people approach their work and interact with one another. It is more than policies or processes—it’s the underlying mindset that guides decisions, defines priorities, and sustains long-term change.

An organization’s culture is defined by its core values, vision, purpose, behaviors, leadership, communication, engagement, and accountability. These elements work together to shape how people make decisions, solve problems, and collaborate. Without this cultural foundation, even the most well-designed strategies risk becoming temporary initiatives rather than lasting practices.

A Reliability Culture is the marriage of two parts: the general components of organizational culture—shared values, beliefs, and behaviors—and the specific objectives of Reliability-Centered Maintenance. It is where the philosophy of reliability meets the daily mindset of your people. In practice, this means an organization doesn’t just implement maintenance strategies; it creates an environment where preserving assets, understanding failure modes, and aligning maintenance with business goals become natural parts of how everyone thinks and acts.

Core Elements of a Reliability Culture

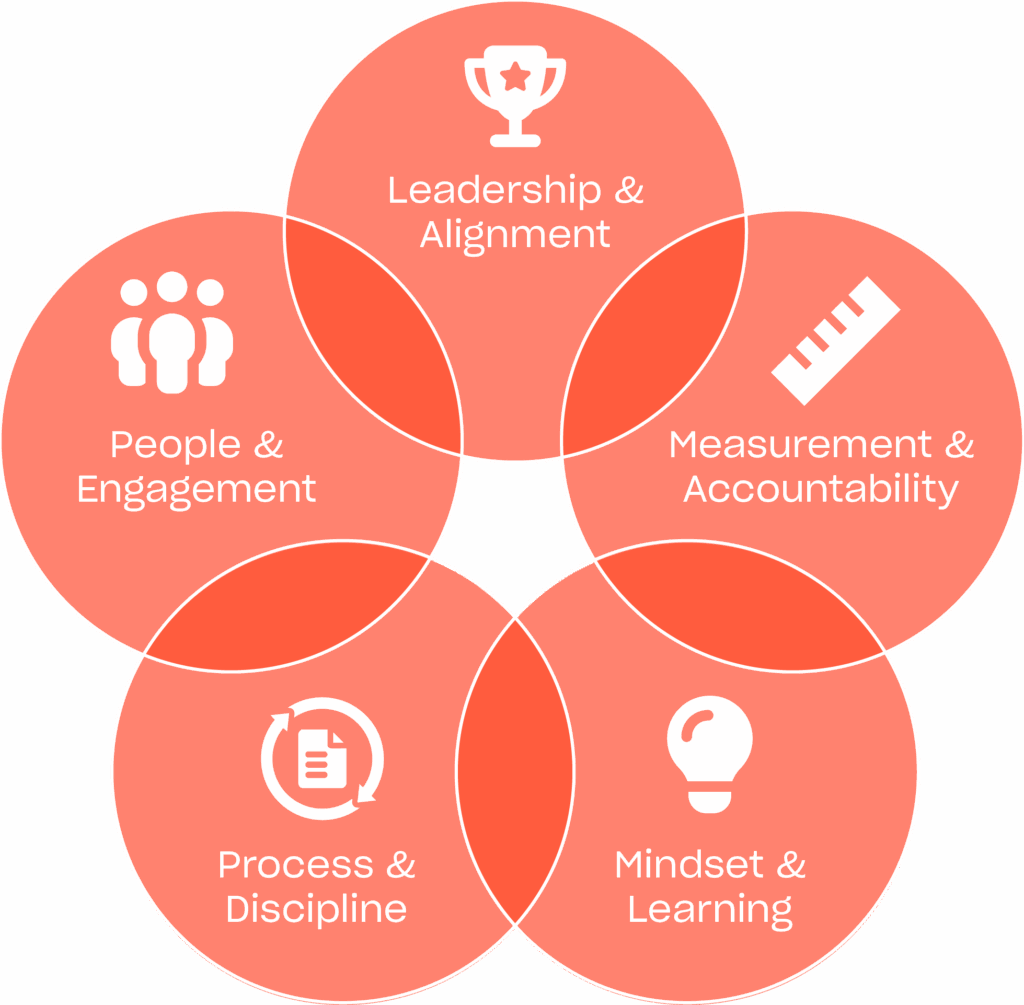

Now that we’ve defined what a Reliability Culture is, let’s look at the core elements that can help you build one. These elements act as practical touchpoints for turning philosophy into daily practice:

Leadership & Alignment

|

People & Engagement

|

Mindset & Learning

|

Process & Discipline

|

Measurement & Accountability

|

Closing Thoughts

Building a culture of reliability isn’t about checking boxes—it’s about creating an environment where reliability is part of every decision, conversation, and action. When leaders set the tone, teams stay engaged, and processes are reinforced with discipline and data, reliability becomes more than a program—it becomes a way of working. By combining the technical objectives of RCM with the shared values and behaviors of culture, organizations can move beyond maintenance strategies to achieve sustainable growth, stronger teams, and lasting operational success.

No matter where you are in your reliability journey, Acoem’s Advisor service can help you take the next step toward building a true reliability culture. By empowering your team to detect problems early and correct them effectively, Advisor gives you the confidence to improve reliability across your entire organization.

Get in touch with us today to find out how we can help.