With the introduction of the OneProd Hawk in April of 2015, VibrAlign shed light on the idea that the future of Machinery Diagnostics was about to get easier; That you can achieve a second level diagnosis on any machine without help from a professional vibration analyst. It just took a tool that empowers mechanics to more quickly troubleshoot a machine at the touch of a button.

Now, almost 3 years later, things may have gotten even easier with the introduction of the Fixturlaser Smart Machine Checker. A successor to the OneProd Hawk, the Smart Machine Checker has taken the process of the Hawk and made it even easier. It’s now a more user friendly, all-in-one machinery diagnostics tool. The Smart Machine Checker includes a built-in machine setup, auto diagnosis and reporting function, thus eliminating the need for installing software on a computer and connecting via the internet to host and access some of these functions. This allows for greater mobility and more flexibility in the field.

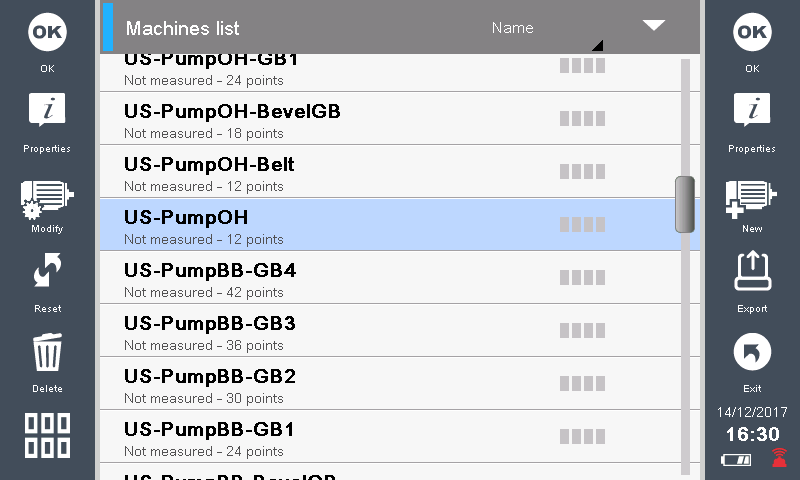

The built in Machine Setup (shown below) allows the user to choose from an extensive list of common machines that have been pre-built for automatic diagnosis.

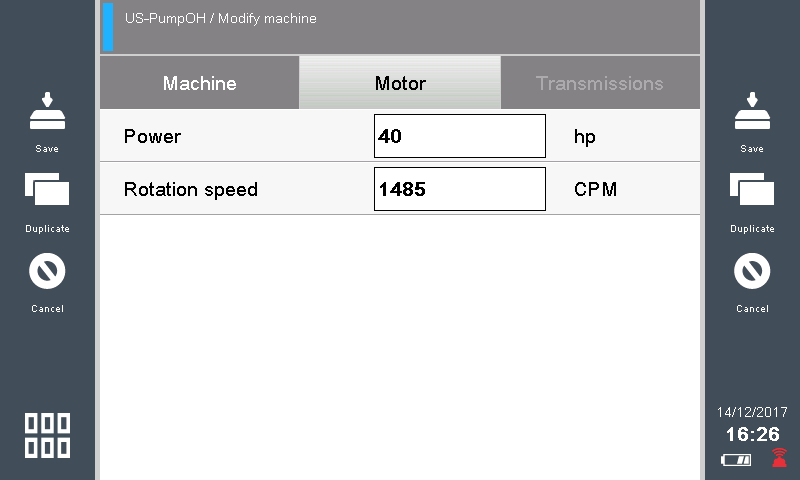

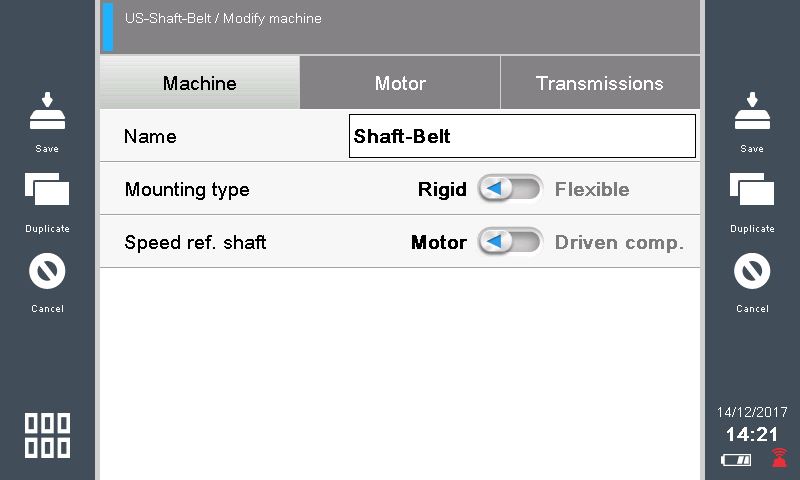

Then, by entering speed, horsepower and whether the machine is rigid or flexibly mounted, you can use the Smart Machine Checker’s wireless triaxial sensor to take measurements on the bearing points of the machine.

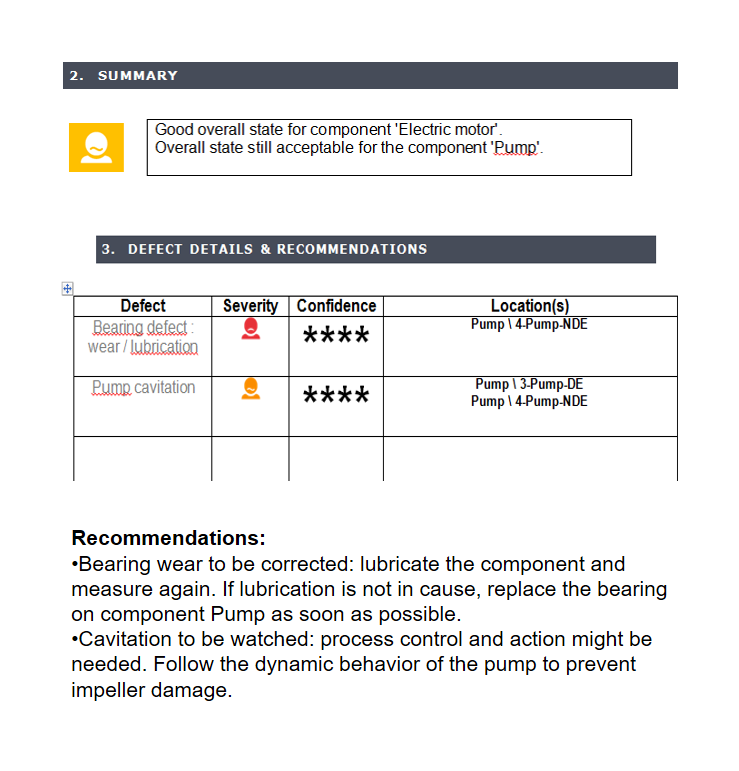

With a few simple steps, you are now able to build and diagnose your machines in minutes, all on the same tool. After you receive a diagnosis, a full report is available on the screen and able to be exported to a USB drive for archiving or editing in Microsoft Word.

The Smart Machine Checker, like the Hawk, provides additional functions to make the diagnosis process as accurate as possible. This includes a built-in strobe light for shaft speed measurements and on-the-go inspections, a pyrometer for bearing temperature measurements, and a camera for documenting your wireless sensor orientation or machine placement. The biggest and perhaps most convenient difference from the Hawk to the Smart Machine Checker is the integration of machine setup software into the tool itself. This results in less time spent in the shop or office and more time in the field, ultimately saving downtime and decreasing energy costs.