When performing the Ariel ER-82 Top Plane Compressor Frame Measurement, surrounding reciprocating compressors in operation may cause repeatability issues due to excessive vibration. To compensate for high/excessive vibration the Sampling Time (measurement time at each measurement location) in the Fixturlaser NXA Ultimate can be lengthened as needed. The NXA has a built in Repeatability Test application the maintenance technician can run to check if vibration is an issue.

To run the NXA Repeatability Test:

First “buck in” the T21 laser transmitter to the RM Sensor per the VibrAlign ER82 measurement procedure. Then place the RM Sensor at the furthest measurement point from the T21 laser transmitter. The RM sensor is in foreground in the photo below.

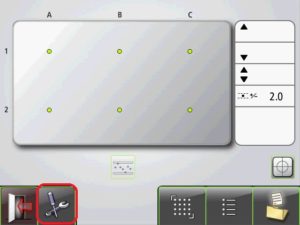

Boot up the NXA Display unit and select the appropriate Ariel Frame Template from the file cabinet and press the rectangle in the lower right corner to go to the measurement screen. Once in the measurements screen press the Tools Icon (settings) outlined in red.

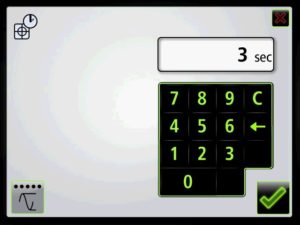

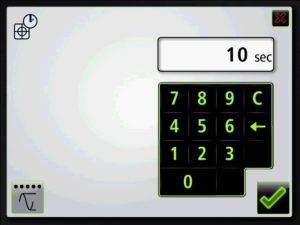

Select the Sampling Time icon. The Sampling Time keypad pops up (factory default is 3 seconds). This is where the Sampling Time (in seconds) can be increased. I recommended to set at 5 or 6 seconds for the gas compression industry if it not already set.

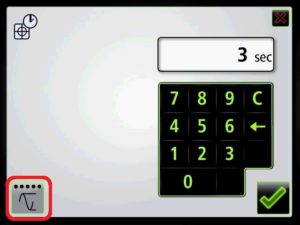

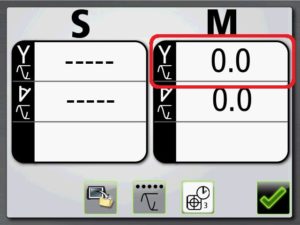

Run the Repeatability Test by pressing the icon circled in red. The NXA will take 5 measurements at the current Sampling Time. If the Sampling Time is set at 5 seconds the test will take 25 seconds (5 measurements X 5 sec each).

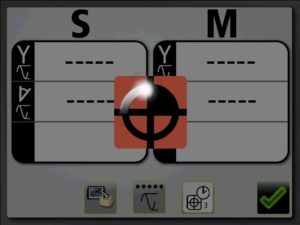

When the Repeatability Test concludes results will be displayed. The M “Y” value shows how much the laser beam is moving across the Y axis (vertical) of the RM Sensor due to vibration. The value displayed is in mils and tenth of mils. (1.0 mil = .001” & 0.1mil = .0001”).

If Y is more than 2.0 mils (the Ariel Tolerance) then increase the Sampling Time 2 seconds and run the test again. The goal is to get the Y value under the 2.0 mil tolerance.

Remember that whatever Sampling Time is entered the Repeatability Test will take 5 measurements x the seconds. So, if the Sampling Time is set at 10 seconds the Repeatability Test will take 50 seconds.

When finished touch the green check mark to exit the Sampling Time and Tools Screen. The Sampling Time will stay set at the current setting (even when exiting the alignment program) until it is changed by the user.

It is doubtful you will need much more than a 10 second Sampling Time to get the Y value under 2.0 mils. Case in point; a client was experiencing repeatability issues during a compressor frame measurement due to several surrounding compressor skids being in operation. After using the Repeatability Test function to select a 10 second sample time all measurement repeated within 0.4 mils (0.0004”). Well within the +/-2.0 flatness tolerance.