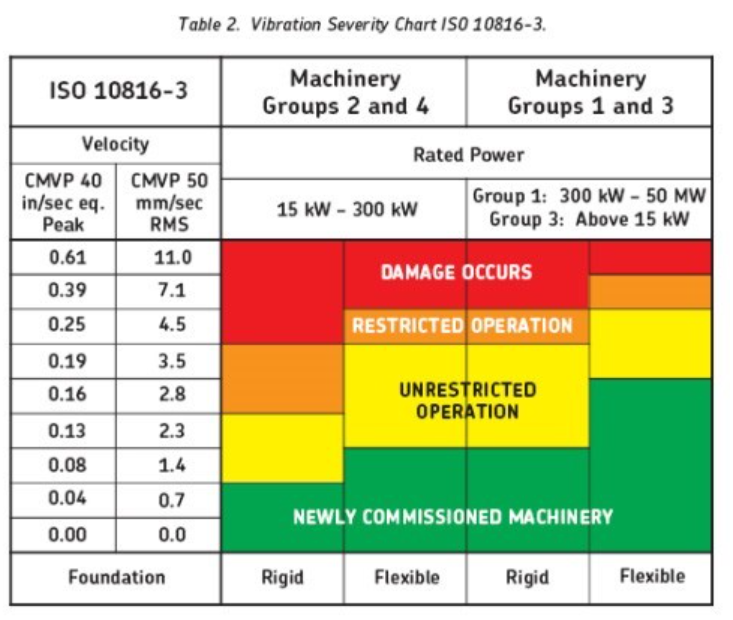

The Smart Machine Checker (SMC), and the Falcon (vibration data collector/analyzer) use Accurex™ automatic diagnostic software to determine vibration problems on rotating equipment. Accurex™ performs a first order diagnostic based on ISO 10816-3 specifications (based on overall vibration levels in velocity, in inches per second/peak, or mm/sec/rms), and a second order diagnostic based on several thousand rules-based algorithms.

To help new users understand the ISO 10816-3 chart, let’s break it down. All machines falling within this specification run at speeds between 120-15,000 rpm.

Group 2 Machines – electric motors and driven machines between 20-402 hp.

Group 1 Machines – electric motors and driven machines above 402 hp.

You’ll notice on the chart that Group 1 machines can tolerate slightly higher levels of vibration than Group 2. This is because larger machines have larger mass, wider stance, and typically can tolerate slightly higher levels of overall vibration.

Each of these two groups are also separated between Rigid and Flexible mounts. Machines mounted on a flexible base, such as isolator springs or neoprene pads, can tolerate slightly higher vibration levels, since these machine’s movements are dampened, or cushioned, by the isolator or pad.

Let’s take a 150hp electric motor, driving a pump, at 1765 rpm, on a rigid base, as an example, and use the ISO 10816-3 chart.

Advised vibration levels in velocity (inches per second/peak)

- Newly Commissioned Machinery – this is assumed to be a new motor and pump, with no wear, operating in a “best case” condition. An overall vibration level of 0.08 in/sec (pk), or 1.4 mm/sec (rms) or less would be expected.

- Unrestricted Operation – this assumes a motor/pump that has been in operation beyond original commissioning. An acceptable vibration level would be below 0.16 in/sec (pk) or 2.8 mm/sec (rms).

- Restricted Operation – the same motor/pump operating a vibration levels between 0.16-0.25 in/sec (pk) or 2.8-4.5 mm/sec (rms) should be considered to have a problem causing excessive vibration, such as unbalance or misalignment. This machine could be run as needed however it should be scheduled for maintenance to reduce the vibration.

- Damage Occurs – vibration levels on the motor/pump above 0.25 in/sec (pk), or 4.5 mm/sec (rms) could cause additional damage to machine components, such as bearings. This machine should be taken out of service as soon as possible, and corrective actions taken to reduce the vibration.

Please note that the ISO 10816-3 chart is for “advised” levels of vibration quality. Some common sense must be used as well. As an example, a machine tool would need to operate at a lower level of vibration, to maintain machining finish quality. A hammer mill might operate at a higher vibration level while in use.

However, for typical industrial machinery, the ISO 10816-3 chart is a good benchmark for vibration quality. Want to know more about vibration analysis? Please contact us at www.acoem.us/contact or call 800-394-3279.

1 Comments

Excellent