Aligning motors to pumps, fans, compressors, etc., it’s what we do. But occasionally we get to assist a customer perform some real “millwright” work!

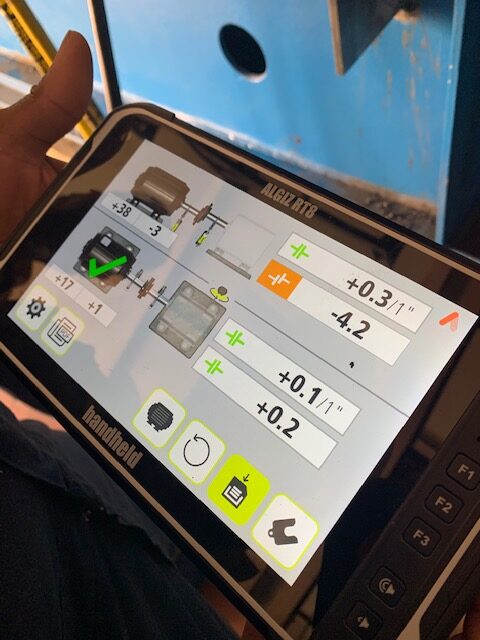

Case in point – a 1000HP Caterpillar engine, driving a backup floodwater pump for a large municipality in the southeast US. This pump is critical to prevent flood water from mixing with effluent at a water treatment plant. This customer had just purchased our RT-300 Solution, which combines laser alignment, automated vibration analysis, and digital Run Out Probe-all in one case.

Alignment Challenges

The challenges with aligning this piece of machinery were:

- The engine had an integrally mounted cooler on the outboard end

- An integrated transmission on the inboard end

- No jacking bolts or lifting bolts, or a usable bridge crane to move a few tons of iron and steel

- The outboard end of the engine was 0.375” too high and it needed shifting to the right 0.805”

Alignment Solution

After reviewing the “as found” results, we offered some advice on how to modify the skid to accomplish the needed moves and gave them a couple of weeks to the modifications. The customer took our suggestions, added jacking bolts to the machine, and slotted some holes.

We showed up a couple of weeks later to perform two days of professional onsite training which included aligning the engine-pump as a class project.

About one hour – start to finish – and they had a well-aligned machine. The engine was set about 4 mils (0.004″) low to compensate for thermal growth.

We also went around with them to perform vibration measurements on a few motor-driven pumps in the facility. The maintenance supervisor said, “Thank you for showing us how to use the RT-300 and to help us “see” what we couldn’t “see” before.

We can help you too! Give us a call! 800-394-3279.

1 Comments

A procedure of how you achieved the alignment is what we need to see and read about.