When companies seek a laser alignment tool, they often struggle to determine which option is best for their specific requirements. Some may opt for a “cheap” solution and choose the least expensive model, while others aim for “the best” without fully understanding what “the best” entails for their situation.

“The best laser alignment tool” is the one that aligns with your goals to enhance reliability, minimize vibration, effectively document your work, and meet the unique demands of your machinery.

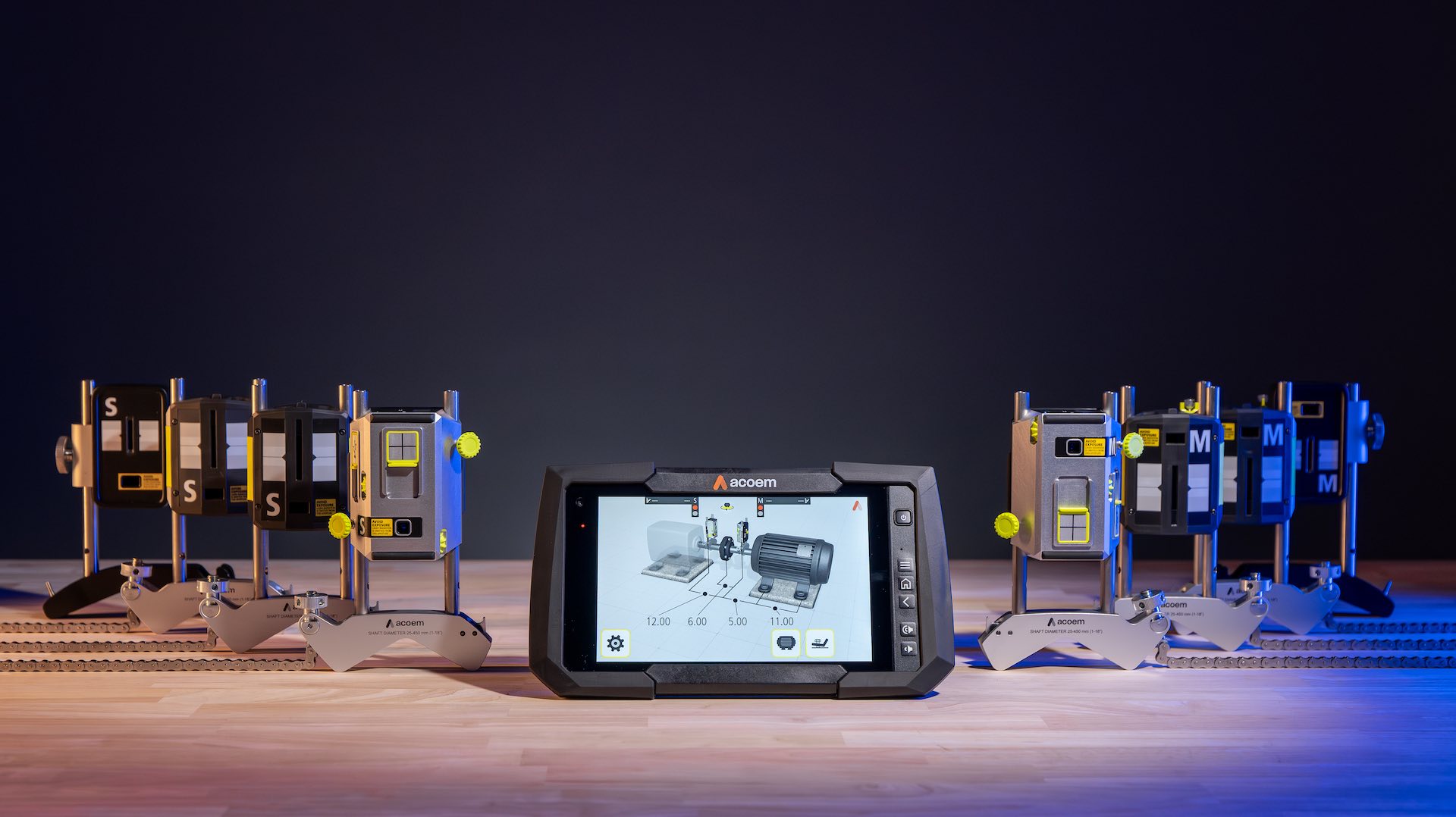

Before making a decision, it’s essential to have a clear understanding of your specific needs. Below is a comprehensive comparison of our AT-Series alignment tools and how they can effectively address your alignment requirements.

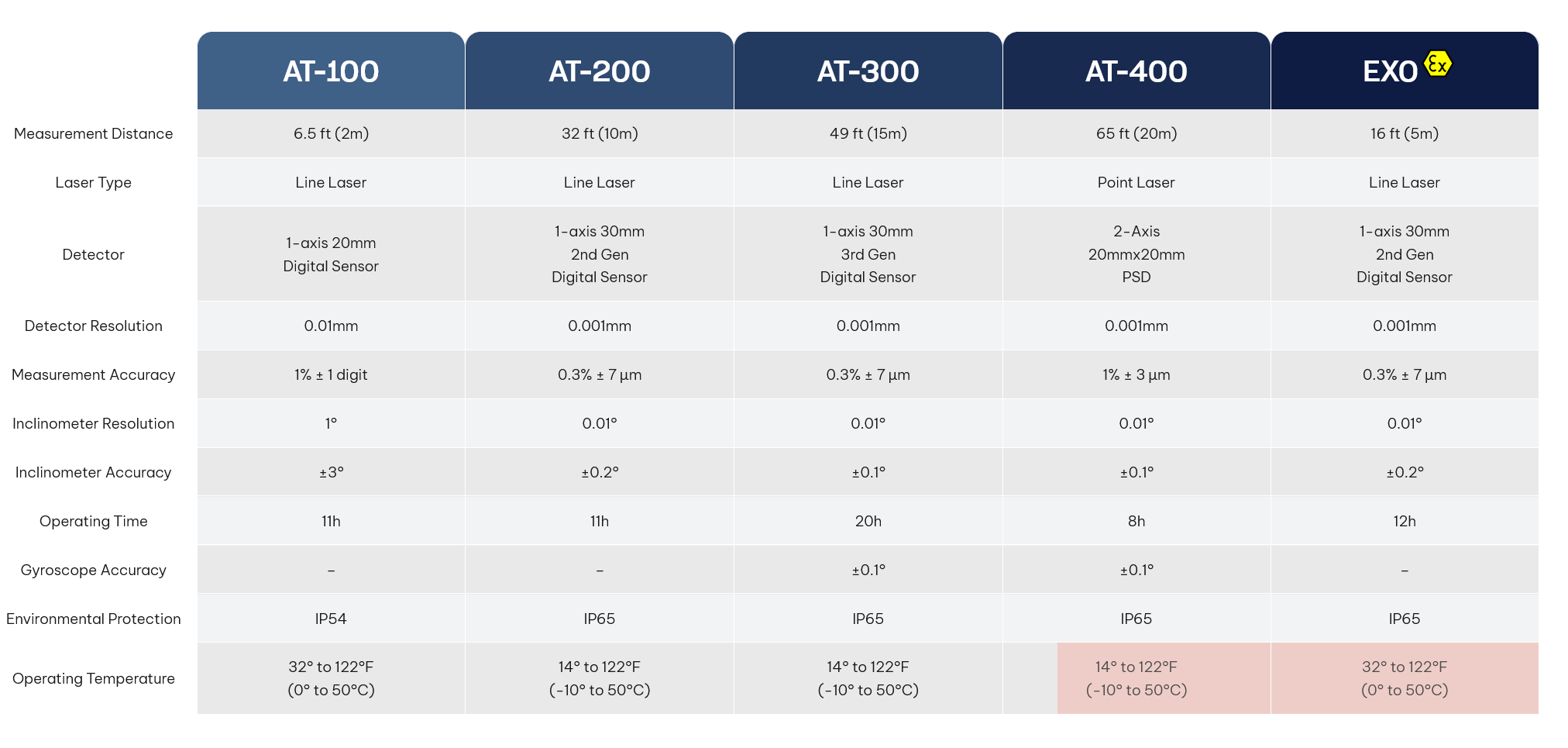

AT-100

- 2-meter range

- Occasional precision alignment of small machines.

- Stock item on a typical service truck or satellite shop, especially when working remotely.

- As a backup laser, especially for outage work or down days, when multiple alignments may occur.

Small ANSI pumps, smaller fans, light to medium commercial HVAC.

AT-200 Essential

- 10-meter range

- When alignment is part of your PM program (if it is not, it should be).

- When you expect bolt-bound or base-bound problems (Feet Lock feature), if your equipment has been in operation for many years, you have pipe strain issues, or your bases are not in good condition, you most likely have bolt-bound or base-bound problems.

- When vibration from nearby machines cause challenges in performing precision alignment.

- Thermal growth targets

- Alignment of vertical machines.

- Cloud access

General industrial machinery alignment, pumps, fans, compressors, etc.

AT-300 & RT-300

- 15-meter range

- When thermal growth needs to be measured (Hot Check)

- Spacer shafts

- Cardan shafts, or universal joints

- Engines or other prime movers, especially those with more than 4 feet

- Flywheels (magnetic base)

- To check for runout on couplings or shafts, measure end play (thrust) or magnetic center, etc. (Run Out Probe)

- *Machine Train (coming soon)

- RT-300 – when you want to check vibration on machines, especially from a field service or new installation, start-up, or acceptance testing.

Medium to large machinery, diesel engines, paper, steel, film, power generation, ships, etc.

AT-400

- 20-meter range

- 2-axis live mode, for monitoring machinery, moves both vertically and horizontally simultaneously.

- Multipoint, Sweep measurement modes

With the Ultimate package

- Flatness Measurements – critical for those who are installing bases to flatness/level specifications.

With the Machine Defender sensor

- Vibration measurements

Industrial machinery installation, base plates, foundations, large or complex alignments, etc.

EXO

- 5-meter range

- When environmental conditions require an intrinsically safe laser alignment tool (ATEX/IECEx Zone 2)

Still not sure which laser is best for you? Your sales representative can help you in the decision, or you can contact us directly at Acoem 800-394-3279. We will be glad to help you pick the tool that best fits your needs.