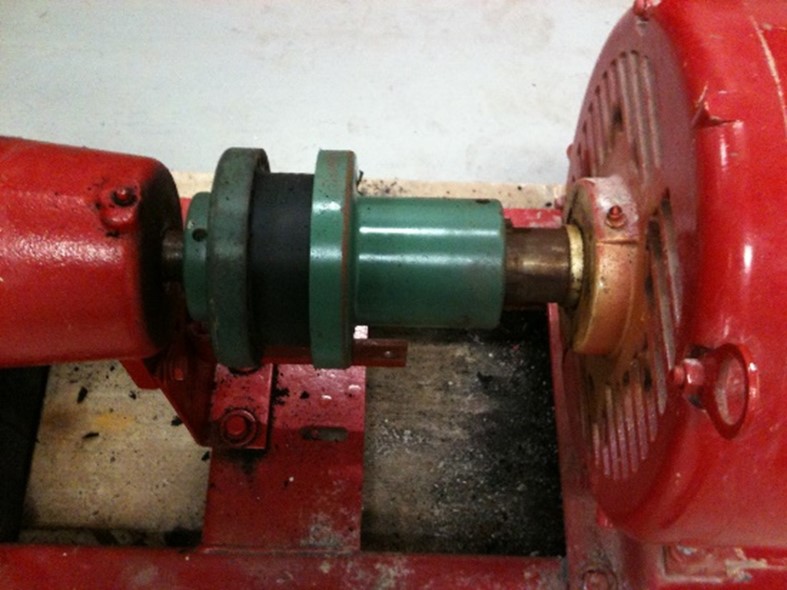

Recently I came across a new pump skid where an alignment check was performed after installation during new construction. Even though it did not have much run time there were already telltale signs of misalignment as indicated by the coupling insert dust on the base. The new pump skid came aligned from the factory:

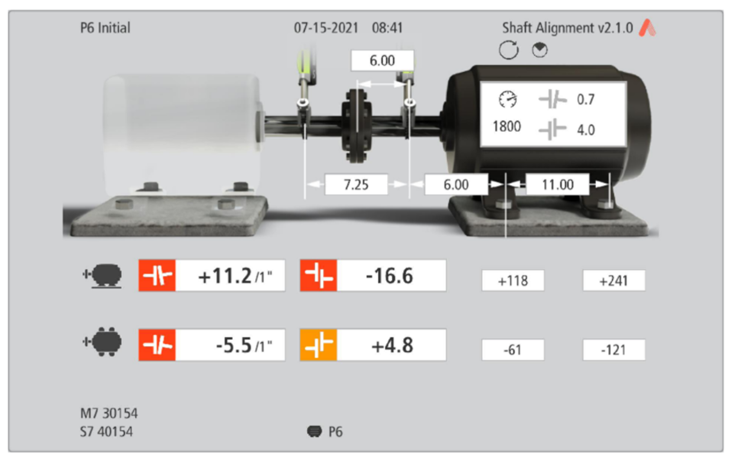

A quick check of the alignment indicated that it was severely misaligned in both the horizontal and vertical planes.

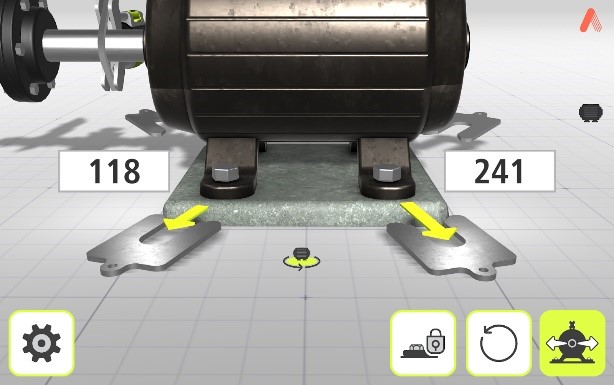

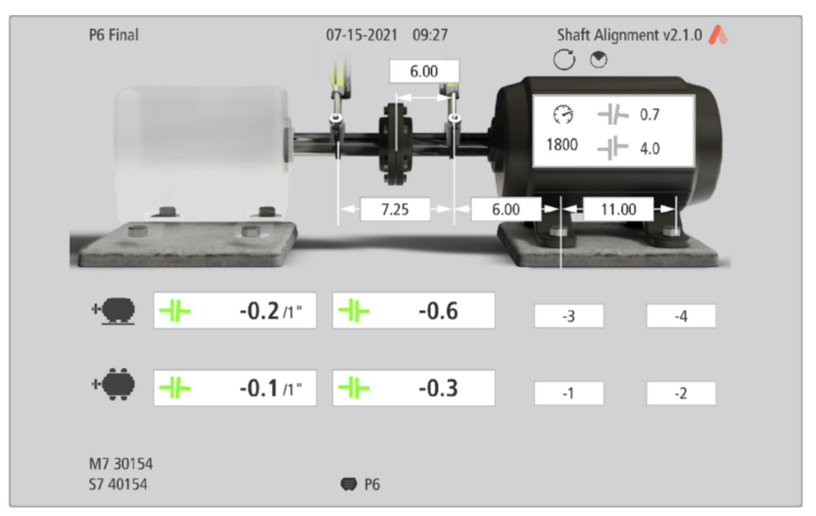

The motor needed to be lowered 118 mils (0.118”) at the front feet and 241 mils (0.241”) at the rear feet. It also needed to be moved horizontally by 61 mils (0.061”) at the front feet and 121 mils (0.121”) at the rear feet.

I suspect that this alignment was performed with a straightedge as the offset values were “close” 16.6 mils (0.0166”) in the vertical plane and 4.8 mils (0.0048”) in the horizontal plane, however the angularity values were not even close with the vertical angle of 11.2mils/1” being 16 times the angularity tolerance of 0.7mils/1” and the horizontal angle of 5.5mils/1” being almost 8 times tolerance.

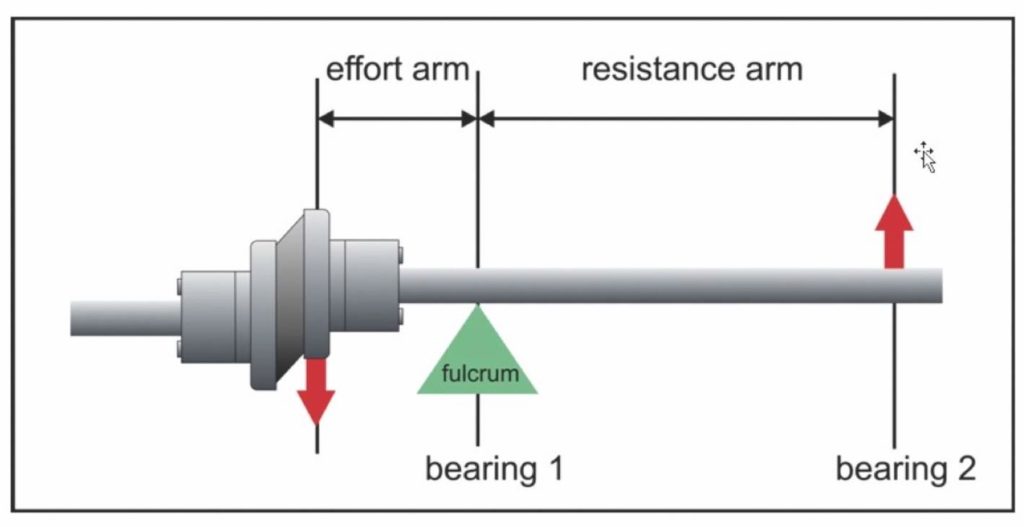

When using a straightedge to perform a shaft alignment you won’t see angular misalignment.

Fortunately, there were enough shims under the motor feet to correct the vertical misalignment without becoming base bound.

There was also enough clearance in the motor feet bolt holes to correct the horizontal misalignment without becoming bolt bound.

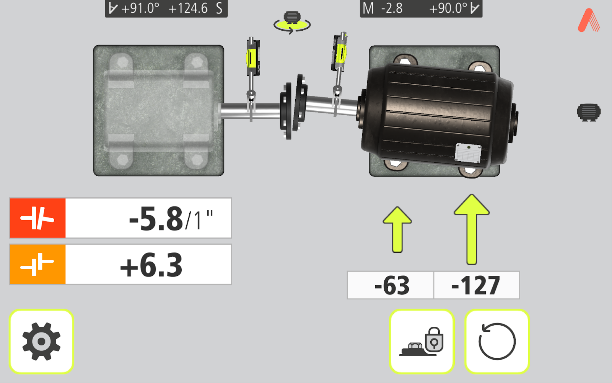

The alignment was quickly and easily completed within 45 minutes, using the Verti-Zontal Process, with the vertical and horizontal angular and offset values better than the excellent alignment tolerances for 1800 RPM. This will greatly decrease the misalignment forces being transmitted across the “flexible” coupling from the motor shaft to the pump shaft. Reducing this force on the bearings, seals, couplings, leads to much longer machine life.

An added benefit will be less energy usage. The cost of owning, operating, and maintaining this asset will certainly be much less than if the precision shaft alignment wasn’t performed.

Here is the final alignment and also pictures of the shims as found and final. Carbon steel painted shims were replaced with clean stainless-steel shims.

This example illustrates the need to check the alignment multiple times during initial rotating equipment installation. Typically, we recommend alignment at the factory to make sure it is alignable then before and after grouting (if done), before and after the piping is connected and six months after installation to check for foundation/base settling.

Additional Resources

Blog Post – The Importance of Alignment and Balance

Energy savings due to precision alignment

Why misalignment draws more current

When a Shaft Alignment Check turns into an Alignment

Alignment Checks as Part of a PM

Shims 102 – Pitfalls of Carbon Steel Shims

How to Read an Alignment Report